Industries use sheet metals in multiple ways. Every project is unique and thus requires specific measurements, metal shapes and sizes. To achieve this, many processes are employed; one is notching, which is widely popular.

However, notching is not as easy as it seems. Whether you are a DIYer or a professional, you should be able to achieve a perfect finish in the result. This blog is all about notching and why mastering the art of sheet metal notching is essential.

Explore this guide with us and learn all the steps to achieve a perfect finish in your sheet metal.

Read on!

The sheet metal notching process involves removing material from the sheet’s edge. It involves creating custom designs on the perimeter, creating rounded edges, or cutting the metal in any way that would serve the project’s purpose.

Sounds easy? It is, if you have the right tools, materials, and machines.

Here are some of the key items that help achieve the best notching results:

Sheet Metal: As the operation is performed on sheet metal, its presence is mandatory for the operation. However, it is crucial to choose the right material, as the project’s success depends significantly on this particular choice.

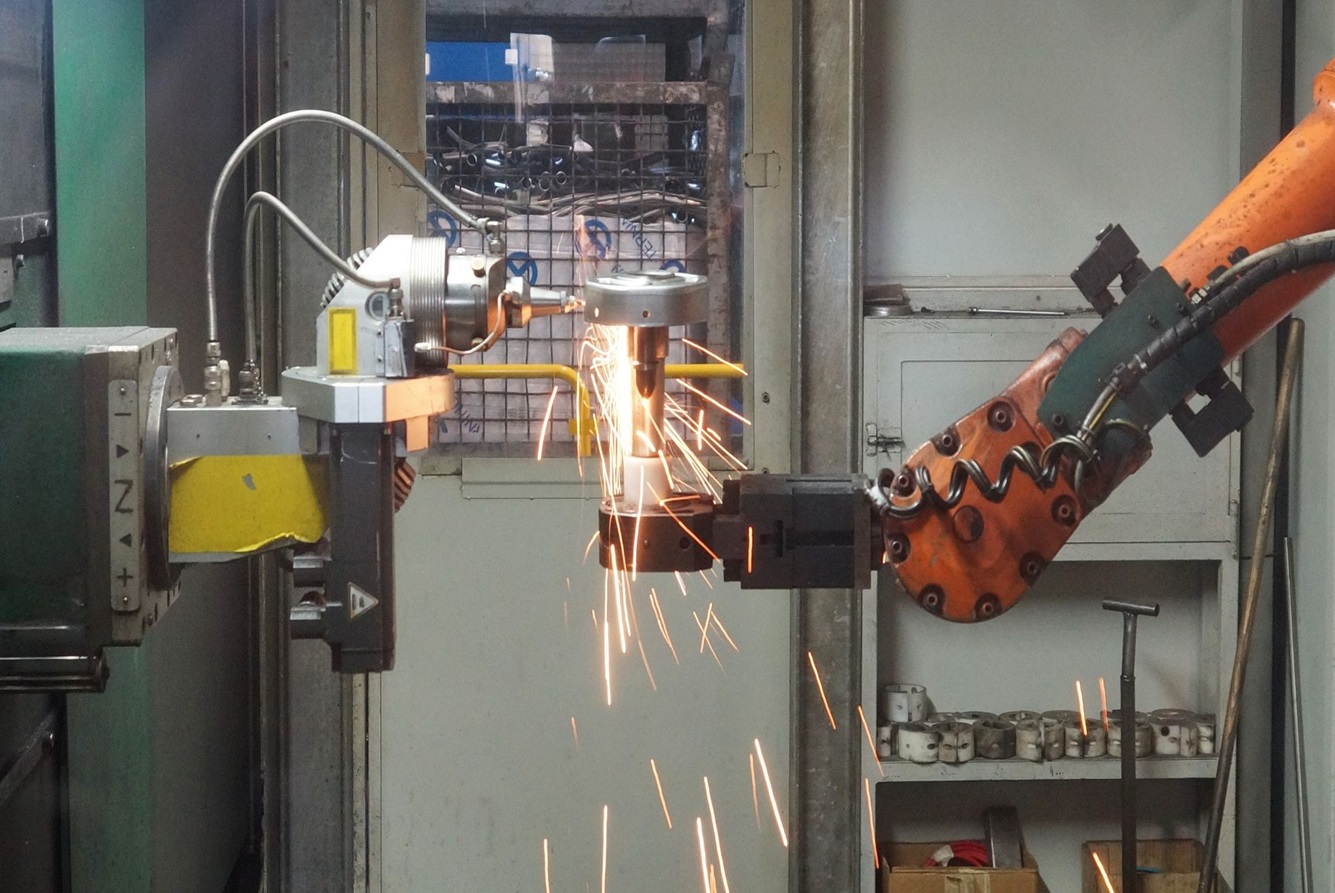

Metal Notcher: A metal notcher is any tool that helps notch the material. It is designed to cut precise notches on the sheet. For smaller notching jobs, manual notchers are a popular option. These are also available in powered options.

Safety Gear: Safety gear is a must for any metal-related operation, considering the nature of the job. The flying debris, the dust, the noise, etc., all of these impact your health, and thus, you need safety gear. It includes hand gloves, safety glasses, ear muffs, etc.

As a DIYer, you need not invest in all these tools, because you might not have a long-term use of the tools. It is advised to seek professional help to ensure your safety.

Check out these essential steps to achieve perfection in any sheet metal notching operation:

The first step is to prepare the sheet metal for the operation. Thus, you should take a ruler or measuring tape and mark where notches will be created. Double-check measurements to ensure accuracy, as precise marking is crucial for achieving clean cuts.

In manual operations, notching is normally achieved without any additional tools. Thus, the need to secure the sheet metal is much more than the automated operations. Ensuring stability prevents unnecessary movement during the notching process, which could lead to inaccuracies.

This step is not necessary, especially if you are undertaking a small notching job with a manual notcher. These are quite straightforward to use and need not require setting up.

The step is crucial where powered notchers are required. Depending on the machines, you must adjust the cutting blades or guides to match the width and depth of the notch needed.

If you use a CNC or another automated advanced technology, the machine shall determine the measurements.

Once the machine is prepared, it is time to align the sheet metal. Position the marked notch lines under the cutting head or blade of the metal notcher. Ensure the sheet metal is aligned properly to avoid crooked or off-center cuts. Activate the sheet metal notching tool and allow it to notch the sheet metal.

Some metal notchers have a lever or a hand crank that requires pulling to activate the notch. Depending on the machine you have, activate the notcher.

The story of manual notchers is different. You must apply steady pressure for every notch to achieve perfection. One deformation can render the entire sheet useless.

After every notching job, no matter how small it is, carefully inspect the edges and corners for any imperfections or burrs. Use deburring tools or sandpaper to smooth out rough edges, ensuring a clean finish.

For large-scale operations, a test fit is recommended. Test the notched sheet metal piece into its intended place and check the fit. If any adjustments are required, make them.

If you are a professional, you can follow the abovementioned steps and achieve perfection.

However, if you are a DIYer, it is wise to consult a professional for a notching job. Multiple aspects of notching should be considered before you attempt it. If you are a beginner and it is your first time using a notch, consult us at New Mexico Metals LLC, and we shall offer the best quality sheet metal notching services.

If you have certain experience in metalworking, the above steps will be helpful.

Mastering the art of sheet metal notching requires practice, precision, and the right tools. As a professional, you achieve perfection over time. However, as a beginner, you neither have the time nor the required tools to practice and master this art.

Thus, we are here for you.

We are New Mexico Metals LLC and happy to offer our services. No matter how small or huge a metal notching job is, we have the tools, machines, and expertise to provide you with top-notch services.

For more information, visit our store anytime.