In this blog, you will learn about metal shearing and other cutting methods, the difference between the techniques used, and which is right for you.

Look around you and spot all the metal objects. Can you see the different shapes, bends, and holes in them and how they have been assembled?

Steel is made of iron and other metals that come together to form the beautiful metal used for various applications. But where does this process start from?

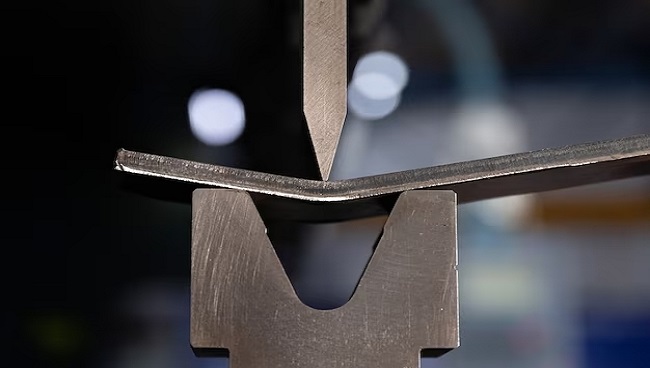

Metal bending is an art. There are thin edges that must be bent accurately; there are thick metal sheets that are bent to use in further operations & extremely hard sheets.

Metal notching is often viewed as “just another” metal-cutting activity that may not seem very important. However, if you are in the metal industry, you will agree that it is a crucial process.

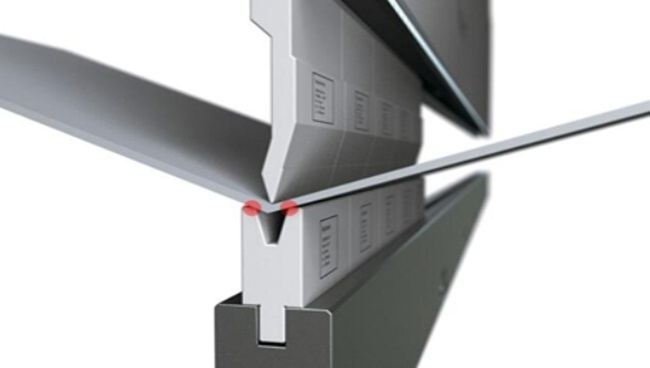

Metal Shearing machines are used to carry out the crucial process of metal shearing, which is indispensable in many industries. The purpose is simple: to shear the metal efficiently and accurately.

Sourcing steel from local suppliers offers multiple advantages, including timely delivery, quick replacement, and prompt customer service in case of a mishap or emergency requirement.

Sheet metal folding? How difficult it can be?” If this is what you think, you are bound to make mistakes. Sheet metal cutting and folding are vital processes used in multiple industries.

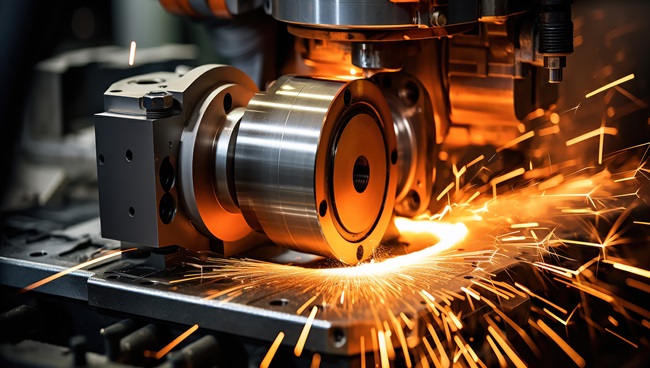

Metal cutting is a fundamental process that has significantly transformed with technological advancements.

Metal punching and notching are two techniques that carve different patterns in metal, while metal bending deforms a metal sheet without cutting it.

Stainless steel is an alloy mainly made of iron, which is a part of daily life no matter where you are and what you do.

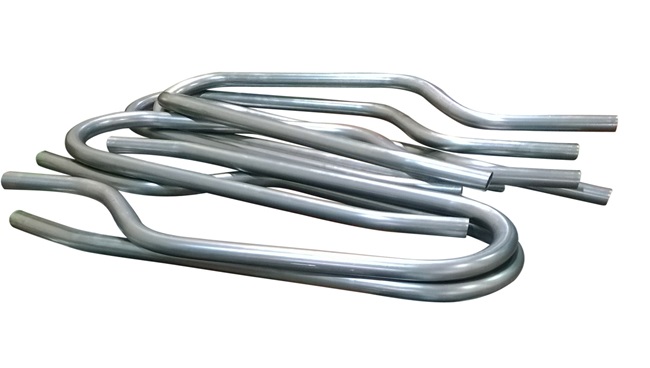

Metal bending is useful for many purposes in multiple industries, where the metal is deformed and shaped without cutting or shearing it.

Metal punching and notching are two techniques that can transform metal into something useful and wonderful.

In manufacturing, you never know where the next challenge will come from. One moment, your engineer might inform you that they need a specific steel grade within a week.

In this blog, you will learn about steel bending, its basics, and how such perfection is achieved at New Mexico Metals LLC.

Electric metal shears have undoubtedly transformed metal shearing.

Choosing the right steel supplier is the key to ensuring the success of your work project.

Sheet metal notching is the process of cutting a metal sheet and clipping the periphery to make it suitable for further use. Simple as it might seem, it is a complex process that requires precision.

Steel bending is a metal fabrication technique used in multiple industries to bend metal sheets at a desired angle to form shapes without cutting or welding them.

In every metal workshop, efficiency and precision are achieved by using the right tools. Shearing is a metal fabrication technique that uses several tools to cut the metal.

Metal notching is the fabrication technique of removing unwanted metal from the perimeter of metal sheets or plates, giving them the desired shape.

The metal fabrication industry might not be a hot topic of discussion on a coffee or dinner table.

Stainless steel is a fantastic metal. Be it its strength, durability, appearance or tensile strength, there are multiple reasons why stainless steel is preferred over other metals.

Metal shearing and cutting are often considered the same; however, they are not. Yes, both of these methods cut metal, but their fundamentals differ.

The metalworking industry can be said to be the most complicated of all, considering the various metals that are used and the various applications that require metal.

Multiple projects at home also require metal drilling. Drilling one simple hole in a metal sheet requires skill, and you cannot always rely on experts.

Metal bending is a metal fabrication process in which the metal is not cut or sheared but bent, maintaining its strength and making it useful for multiple processes.

While efficiency and precision are paramount, metal notching professionals seek new technologies to make the work more efficient, detailed, intricate, and perfect.

When you look at holes in a sheet, they look easy enough to create, right? However, when you engage in metal punching yourself, you realize that the simplest task is daunting and requires precision.

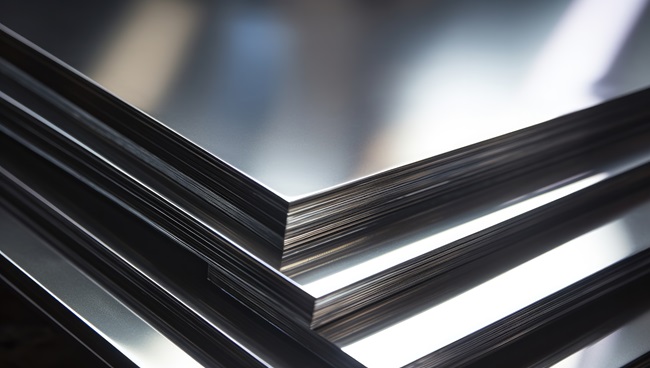

When looking for a versatile metal option for construction, industrial use, or personal DIY projects, stainless steel sheets stand out as one of the best options, owing to their distinct features and versatility.

The world of metallurgy is quite unique, transforming metals into numerous intricate shapes and designs and offering convenience and comfort to our daily lives.

Stainless steel sheets are versatile, and thanks to their wonderful corrosion resistance properties, they are in demand for multiple reasons.

With a significant lean towards sustainability, the industry is transforming, and customers are demanding products with zero carbon footprint.

Metal cutting is a fundamental process, and as technology advances, so do the tools for metal cutting, bringing innovations that redefine precision and efficiency.

Metal shearing is a popular metal fabrication method that has evolved over the years. Metal shearing refers to the process of metal cutting into smaller parts.

Modern architecture is transforming, and stainless steel is playing a vital role in it. Its timeless, strength, and durability make it a preferred choice for various industries.

While steel is a robust metal widely used across multiple industries, it is also impacted by environmental conditions and, thus, requires protection.

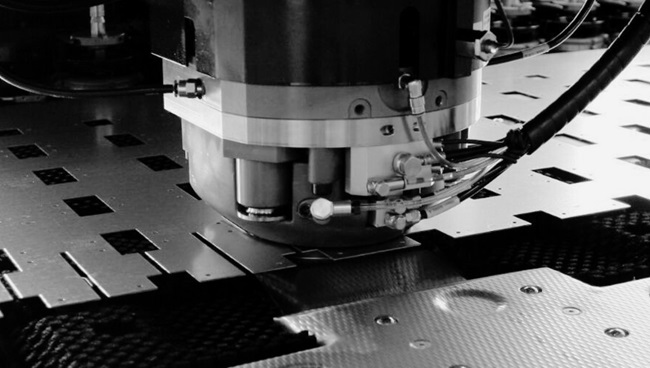

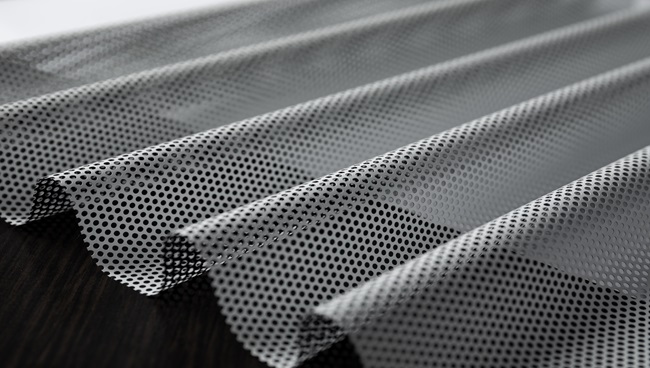

Sheet metal processing demands precision and reliability. When you are choosing sheet metal for any further process, you want to ensure that it is the best quality sheet metal parts.

The evolution of metal fabrication has progressed significantly from ancient times when humanity had limited knowledge of a few metals, and all processes were manual.

Artificial Intelligence is everywhere. Be it creating a simple image or a complex process like metal shearing. Metal shearing is the process of removing unwanted metal from a sheet metal.

Quality steel is not a magical invention. Instead, it is the result of rigorous quality steel control and testing, which ensures that the steel produced after the long process is of top quality.

Sheet metal processing is the process of rendering sheet metal useful for multiple purposes by drilling, sawing, and shearing. Sheet metal is used in several industries, including aerospace and household appliance manufacturing.

Automation, the Internet of Things, Industry 4.0, etc., are some of the concepts used widely across all industries. The aim is to improve efficiency, boost production, and reduce costs.

Metal shearing is a popular metal fabrication process that is used to remove unwanted metal from a metal component, be it a sheet or plate.

Sheel metal bending is an underrated process useful in engineering and manufacturing. Especially when mass production is concerned, sheet metal bending is crucial.

Steel is a metal that’s everywhere, and yet very few people know its manufacturing process. Do you know how steel is manufactured and reaches your kitchen or bathroom in the form of knives or faucets?

Metal fabrication is the distinct process that renders a valuable metal for further processing or transforming into finished products. It includes metal cutting, sawing, shaping it through bending and shearing.

Metal shearing is widely used in several industries to cut and trim metal sheets and metal plates precisely.

Whether you are a metal fabricator or a DIY enthusiast, there will be times when you will face the challenge of choosing one of the two methods of joining metal and making new components.

Metal shearing is a metal fabrication process widely used for removing unwanted metals from sheets to render them useful for further processes.

Metal is a hard substance and requires due consideration in sawing. Be it stainless steel, aluminum, iron, or any other metal, cutting through is challenging, and one must choose the right blade for metal sawing.

Stainless steel is in demand across many industries owing to its versatility. As we look ahead to the future and think about stainless steel’s role in shaping it, there are many trends and predictions that can be found.

Steel metal bending is a delicate dance between precision and technique, and at New Mexico Metals LLC, the best metal supplier in Albuquerque.

Electroplating is a type of metal finishing that involves depositing a thin layer of metal on a substrate metal. Different metals, such as gold, silver, zinc, and nickel, are used in electroplating.

Anodizing refers to adding another layer of protection on the metal’s surface, which not only thickens the metal but enhances durability and improves the appearance of the metal.

Steel bending in Albuquerque is a fundamental process that transforms sheet metal into three-dimensional, meaningful shapes. It takes only seconds for a sheet to be turned into a shape.

It is a commonly asked question whether one can weld pot metal. Yes, it can be welded, but it significantly depends on your alloy. It is not a straightforward method that applies uniformly.

Metal cutting saws have been used for shaping metals for centuries now, and they have only become powered with automation, but they are still popular.

Stainless steel is a very popular metal. It is a multipurpose metal used for manufacturing everything from a tiny needle to creating massive bridges and buildings.

Stamping and punching are two crucial metal fabrication techniques. Distinct industries require different metals converted into specific shapes and sizes for multiple operations.

Metal shearing equipment, i.e., the machines and tools used for metal shearing in Albuquerque, are crucial sets of equipment.

Be it the manufacturing of a small mechanical part or an aircraft, metal drilling is essential. It refers to drilling holes in the metal to help join parts with the metal.

Aluminum is a preferred metal across various industries due to its several properties. One of the outstanding features of aluminum is that it is a metal that can be recycled numerous times, and it won’t lose any of its properties.

Steel fabrication is an art. It is not everyone’s cup of tea, and it requires a great deal of precision, patience, and determination to work on something that you can mold into whatever shape is needed with as much perfection as possible.

The metal sawing process is crucial for various industries. This process is an indispensable method that ensures that the industries get the metal in desired shapes and sizes.

Stainless steel is a widely used metal for manufacturing everything, from your kitchen sink to huge skyscrapers. It is a metal that has earned its place in nearly every industry due to its properties.

A building is not just a structure of concrete but a structure of hope & security. Whether you are working on a housing or industrial project, metal is vital in strengthening a structure.

Hole punching is a metal fabrication process that is crucial for several activities. You must be thinking that punching holes in metal shouldn’t be difficult.

Metal sawing is a metal fabrication process for substantial metal projects. This article explores Albuquerque’s cost-effective metal sawing solutions, including their benefits & drawbacks.

Steel is an important building material in the construction industry. It is used in almost every construction project, from skyscrapers to bridges.

It is essential to take safety precautions to avoid accidents and injuries. This article will discuss the five metal bending safety precautions you need to know.

When it comes to metal supply, choosing the right supplier is crucial. With so many options out there, it can be overwhelming to find the perfect fit.

Sheet metal punching is a cutting process that helps in shaping metal forms. Advanced skills and equipment help punch holes in the toughest metal pieces.

In its most basic form, stainless steel is made up of steel (iron and carbon) and at least 10.5% chromium. This alloying element gives stainless steel its signature resistance to corrosion and rust.

We’ll explore the unique properties of stainless steel that make it well-suited for forming custom precision steel parts, as well as some common applications where stainless steel is used for precision fabrication.

Steel is one of the most widely used materials in the world, with applications in construction, manufacturing, and transportation, among others.

The importance of metal fabrication cannot be overstated, as it plays a vital role in manufacturing, construction, and many other industries. In order to create metal parts…

Bronze is widely used in industrial settings, parts, and decorative structures.

We offer several grades of Bronze and related metal products at New Mexico Metals LLC. So, you can trust us for your bronze needs in Albuquerque.

For an ordinary person, steel is steel, but if you ask an expert, there are stainless steel, steel, carbon steel, & many more. Including the word steel in the name does not make carbon and stainless steel similar.

Stainless steel is used in many applications, be it in your kitchen or the construction of heavy bridges. The metal’s physical characteristics, such as its beautiful shiny finish or strength, have rendered it worthwhile for every process.

These powerful machines are designed to easily drill precise holes through hard metals, making them invaluable for anyone who offers metal drilling services Albuquerque area. However, with a wide range of options on the market, it can be hard to know which one is right for you.

Have you ever wondered how metalworkers create those perfect, clean cuts in various metals? Well, wonder no more! The notching process is the answer. This metalworking process is used extensively to manipulate and shape…

Metal shearing is a popular process used in sheet metal fabrication. It involves cutting a piece of metal along its length to create a specific shape or size. Unfortunately, this process can sometimes lead to defects in the product…

Stainless steel is known for being strong, long-lasting, and looking good in almost any situation. It is one of the most versatile materials, with uses ranging from medical equipment and cutlery to auto trim and airport roofs.

Sheet metal bending is a process in which a sheet of metal is deformed plastically to create the desired shape. The process is performed by applying force to the sheet. The pressure then causes the metal to yield and take on a new form.

Steel sheets and plates are one of the most versatile types of metal products on the market. Essentially, they are large, flat pieces of steel that can be cut and welded to create all sorts of structures and products.

Steel is an iron-carbon alloy whose properties make it indispensable in the tooling industry. Its hardness, durability, and resistance to wear and tear make it an ideal material for making tools. However, not all steels are created equal. Different steel grades have different…

Casting is an ancient technique that has been used for centuries to create all sorts of objects, from simple tools to elaborate sculptures. The basic principle behind metal casting is simple: a mold is created,…

If you are a DIY enthusiast who loves working with metals, you probably have encountered the difficulty of making holes in hard metal. It is not an easy feat, but with the right tools and techniques, you can make perfect holes in any type of hard metal,…

One common process in metal fabrication is bending. Bending metals allows you to create various shapes and sizes for your project. But how do you go about bending metals? This article will focus on the metal bending process.

Rolling is a process where metal is passed through a pair of heavy rollers, which compress and shape the metal into desired shapes and sizes. Rolled steel is classified into two types-

Making up more than eight percent of the Earth’s crust, aluminum is the most abundant metal in the world. That means there’s plenty to go around for construction workers who can make use of its many benefits.

As the world continues to modernize, people are constantly on the lookout for new ways to make their lives easier. Stainless steel is one of those materials that have made a significant impact in recent years due to its many benefits.

With the inception of the Industrial Revolution, many industries switched from manual production processes to machine-aided ones. Metalworking is one such industry that has seen a significant change in the way products are manufactured.

Metalwork is a popular hobby and profession, and many different types of metal can be used for various projects. In this blog post, we will compare two of the most common metals for this type of work, aluminum versus stainless steel,

Metal sawing requires technical expertise, the right tools, training, and equipment to make the right cuts. It isn’t easy and shouldn’t be undertaken if one lacks proper training.

We offer premium metal sawing services

Everyone knows that steel is made from iron ore, but how is it made? Do you know it? If not, this guide is for you, where you will learn how iron can be converted into shiny stainless steel. Two processes…

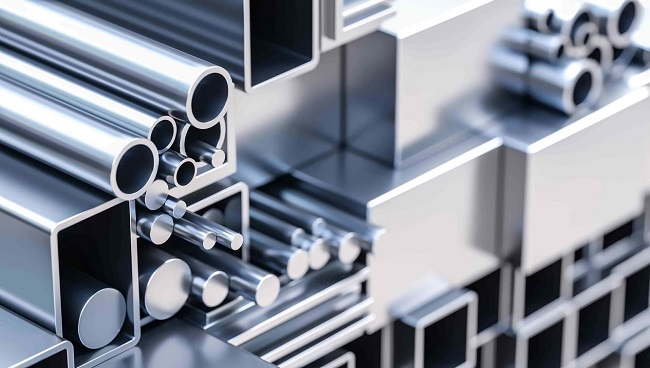

Metals can be mixed and matched to create different properties or to create entirely different alloys. Some of the different types of metals and their uses are discussed above. It will help you choose the right metal for your project.

With a local metal supplier, you can visit them any time and you can choose the product that best fits your needs without guessing. It also allows you to change your mind when you can find a better option for your project or job.

Steel is used in various applications. From kitchen utensils to structural components, it is used everywhere. But do you think that the same grade of steel is used for all different..

Metal cutting requires precision, clarity, and minimum possible waste. Several methods are used for cutting, but which one is best?