For centuries, man has used metals for different purposes. There are various types of metals around you. Some metals are more popular than others as they are used more commonly.

In this guide, you will learn about different types of metal and their uses.

The five popular metals are steel, aluminum, iron, zinc, and bronze. For years, man has learned various uses of metals. Some of which are discussed here.

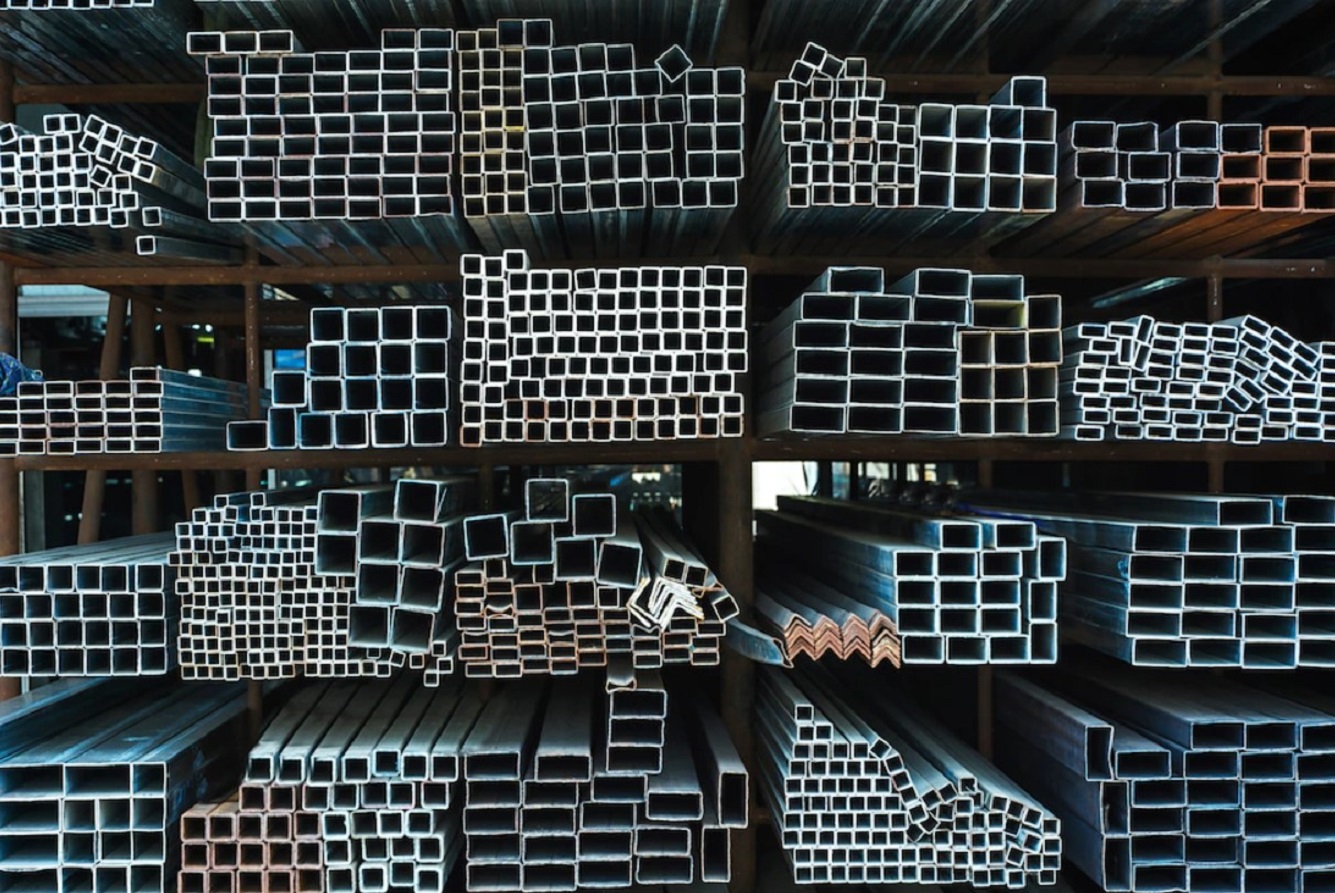

Steel is the most widely used metal today. It includes stainless steel, alloy steel, carbon steel, and various types of tool steel.

Steel has iron as its main component. When different types of elements are mixed with it in different quantities, they create different types of steel.

Mixing 0.05-0.95 percent carbon creates carbon steel. Steels with lower carbon are called mild steel. It is known for its strength. A higher percentage of carbon results in higher strength and low ductility.

Low carbon steel has high ductility, and thus it is used for structuring purposes such as automobiles, construction sites, food cans, pipes, etc.

Medium carbon steel is hard, and thus it is applied where strength is the prime deciding factor for choosing metal. It is used in manufacturing railway tracks, machinery, crankshafts, train wheels, etc.

High carbon steel is used in making dies and high-strength wire ropes, high-strength bars, pre-stressed concrete, etc. Steels over 1.0% and up to 2% carbon are regarded as tool steels and can be hardened to make dies and cutting tools.

Alloy steel is created by mixing different elements in its manufacturing. Nickel, chromium, boron, manganese, vanadium, molybdenum, silicon, etc., are some elements, mixed in the ratio of 0.1-50 percent to make the steel suitable for varied applications.

Low alloy steels are known for their strength, machinability, and heat-treatability and, thus, are used in multiple industries, such as the manufacturing of military vehicles, ships, oil drilling platforms, pipelines, etc.

High alloy steels can be hard to process and thus are used in the manufacturing of airports, buildings, bridges, etc.

Stainless steel is a type of steel that includes 11% Chromium and other elements. It is much less prone to rust, but its surface can be polished to a high gloss which makes it desirable aesthetically. It is machinable and less prone to rust when compared to other types of steel.

Stainless steel is widely used in various industries. It is used to manufacture culinary items, utensils, knives, surgical equipment, architectural buildings, aircraft, bridges, etc.

Aluminum is the most abundantly found metal on earth. It is a mild non-ferrous alloy that is mixed with different elements in different ratios for various applications. Includes 99.5-99.9% aluminum and 0.12-0.05 % copper as its major components. It is lightweight and malleable.

Aluminum is preferred in the transportation industry and primarily in the aviation industry, owing to its strength-to-weight ratio. The aerospace industry relies heavily on aluminum for manufacturing space shuttles and other components.

It is also used widely in the construction of buildings and in manufacturing electrical components, such as wires, long-distance power lines, cables, power systems, motors, etc.

Iron is a ferrous metal that forms most of the earth’s core. It is a hard metal that rusts easily. It is refined and mixed with different elements to create different types of steel and other metals. Due to its hardness and strength, it has varied applications.

Cast iron is used in manufacturing weapons and tools like it was used in ancient times. The process requires a die to make the mold or shape of an item and then liquid iron is poured into the mold to make the final shape. Due to its high compression strength, it is used in many structural applications, such as buildings and bridges.

Zinc is found abundantly in the earth’s crust. At room temperature, it is brittle and light grey in color. It is generally alloyed with different metals to make it suitable for various applications.

It is used in making batteries. It is also used for galvanizing steel, chemical production, and die casting. Its most common alloys are brass and bronze alloys. Its major applications include manufacturing products such as plastics, batteries, pharmaceuticals, textiles, batteries, cosmetics, electrical equipment, paints, etc.

Bronze is a red metal. Its distinct red color makes it fall into this category. It contains copper and tin as its main components and is also alloyed with different elements to create different properties.

It is a hard and brittle metal that is reddish brown in color and is non-corrosive.

Due to its high corrosion resistance, it is used in marine and fishing equipment.

It is used widely in electrical components such as motors, wires, connectors, and springs.

It is also an artistically popular metal used for making musical instruments and other art pieces.

Every metal has distinctive properties and characteristics, and their applications depend on their properties. Metals can be mixed and matched to create different properties or to create entirely different alloys. Some of the different types of metals and their uses are discussed above. It will help you choose the right metal for your project.