The world of metallurgy is quite unique, transforming metals into numerous intricate shapes and designs and offering convenience and comfort to our daily lives. It is wonderful how a raw material that is unidentifiable in its true nature is converted into aesthetic sheets, pipes, and other objects.

Aluminum is a fantastic metal that amazes people with its quality and versatility. Aluminum oxide plays a pivotal role in transforming raw aluminum into high-quality sheets.

To know more about the details and the process, read the blog.

The aluminum industry is booming. With the advancements in the metal industry, its applications have expanded to a diverse range of sectors. Aluminum’s popularity is attributed to its lightweight nature, corrosion resistance, and remarkable conductivity. The industry’s growth is fueled by innovation, sustainability, and the demand for high-performance materials.

The shiny, sleek aluminum comes from bauxite. It is a mineral obtained from only a few feet below the ground. Aluminum is abundant in the Earth’s resources. In fact, you will be amazed to know that the total aluminum demand is fulfilled by only 45% of the deposits.

The mined bauxite is grey and has several impurities, including red mud, sand, and other solid and soluble particles, which are extracted from the alumina at different stages of refining.

Around the world, multiple methods of bauxite refining are used; however, the most affordable one is the treatment of ore with lime and soda.

The ground bauxite is pumped into large pressure tanks along with caustic soda, making a smooth metal slurry when injected with steam heat and pressure.

The material then follows into pressure-reducing tanks where the material is exposed to atmospheric pressure. From here onward, the insoluble materials, such as red mud, beach sand, and other particles, are separated from the alumina.

Afterward, aluminum hydroxide is added to the solution, which attracts other crystals. The crystals come together and form agglomerates, which are washed with chemical water to leave pure aluminum.

At this stage, aluminum looks like a shiny powder, bonded with the same amount of oxygen, binding them forever.

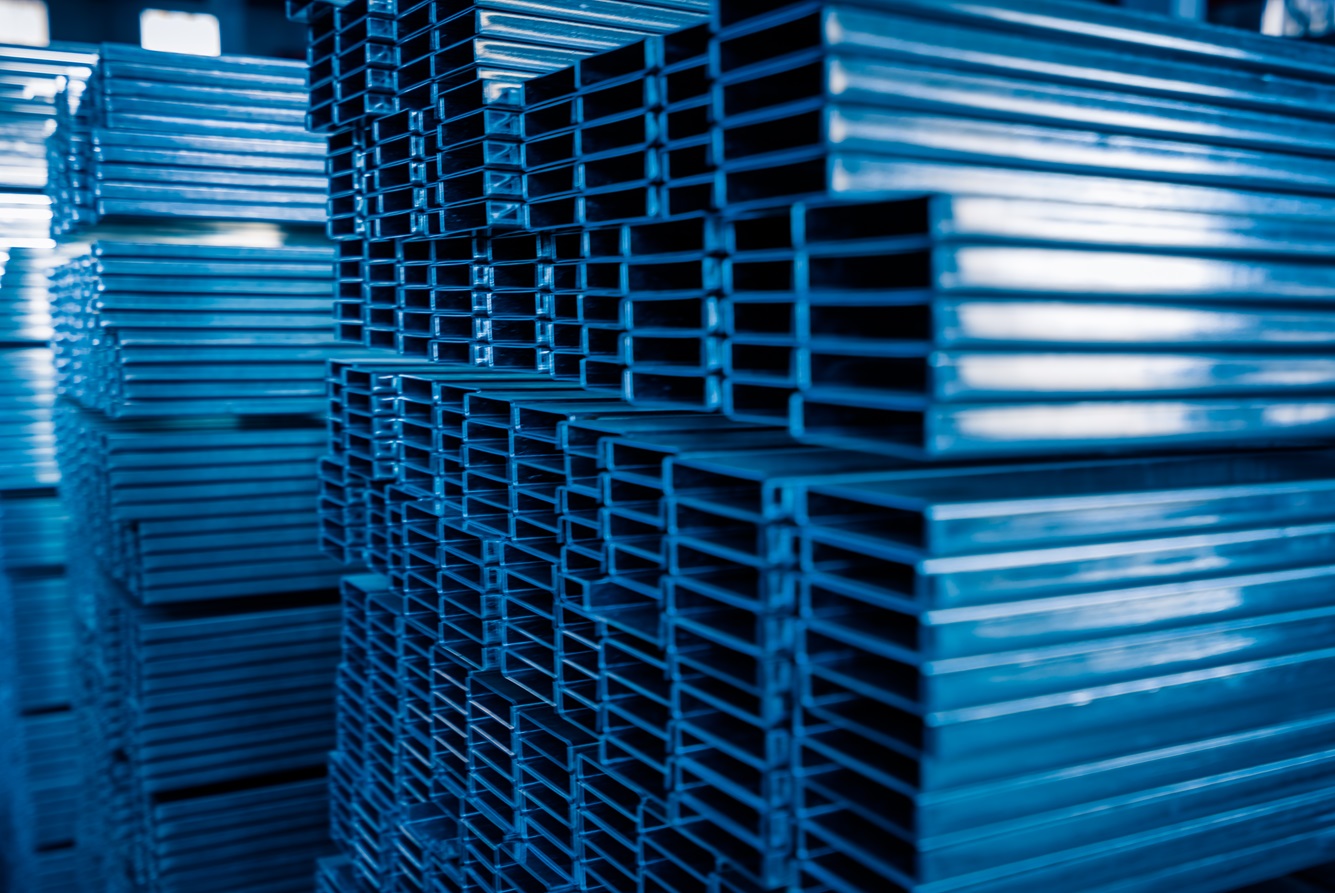

The process of crafting aluminum sheets is as follows:

The metal is melted and formed into blocks called ingots, which are then used to make other finished products.

The ingots are heated and rolled into thin sheets. The rolling process involves passing the aluminum through sets of rollers, gradually reducing its thickness to the desired gauge. Casting, another method, involves pouring molten aluminum onto a moving belt, resulting in continuous sheets.

The rolled sheets require finishing, which involves multiple methods to make the metal look more aesthetically pleasing. Annealing, polishing, coating, grinding, and buffing are the processes that give aluminum its shiny, finished look.

Aluminum sheets have multiple applications, ranging in various industries. Some common applications are discussed here:

The efficiency of motor vehicles is defined by the fuel they consume. The heavier the vehicle, the more fuel it requires. Aluminum is a metal that contributes to the lightweight construction of automobiles, aircraft, and marine vessels, making them efficient.

If you look at modern architecture, you will find multiple aluminum components, including window panes, doors, sliding roofs, cladding, etc., as their corrosion resistance makes them ideal for the construction industry.

The malleability of aluminum allows it to be easily shaped into packaging materials, such as cans and foils, providing a lightweight and recyclable solution.

Aluminum is known for its thermal conductivity and is thus used extensively in the electronics industry.

The economics of aluminum production are influenced by various factors, with the cost of raw materials being a significant component. Bauxite mining, alumina refining, and transportation contribute to the overall cost structure. The market dynamics, geopolitical factors, and sustainability initiatives also impact the economics of aluminum production.

The journey of aluminum from raw material to aluminum sheets is quite exciting as it passes through multiple phases of innovation and transforms into multiple beautiful components. The importance of aluminum oxide as a catalyst in ensuring quality highlights its crucial role in influencing the characteristics of the end product.

As an end user, the process might not be exciting for you, but it determines the product quality you will procure.

So, when you procure aluminum from a supplier, you must learn about its quality.

For the best quality aluminum, visit New Mexico Metals LLC, as we believe in delivering quality.

Give us a call now!

Que: Is aluminum an environment-friendly material?

Ans: One of the reasons for aluminum’s popularity is its recyclability. It can be recycled multiple times, which makes it the first choice for various purposes.

Que: What makes aluminum popular in the construction industry?

Ans: Aluminum’s corrosion resistance is the reason for its extensive use in the construction industry.

Que: What are the sustainability practices in the aluminum industry?

Ans: Aluminum production requires extensive energy use, which causes environmental concerns and thus requires measures for aluminum recycling.