Steel plate/ sheet bending and steel tube bending might sound similar, but the basic structure of the two makes the bending process quite different. Steel tube bending refers to bending the tube or pipe to achieve a certain angle. The use of machines, the skills of the technician, and the steel metal grade, thickness, and type also affect the bending results.

In this blog, you will learn about steel bending, its basics, and how such perfection is achieved at New Mexico Metals LLC.

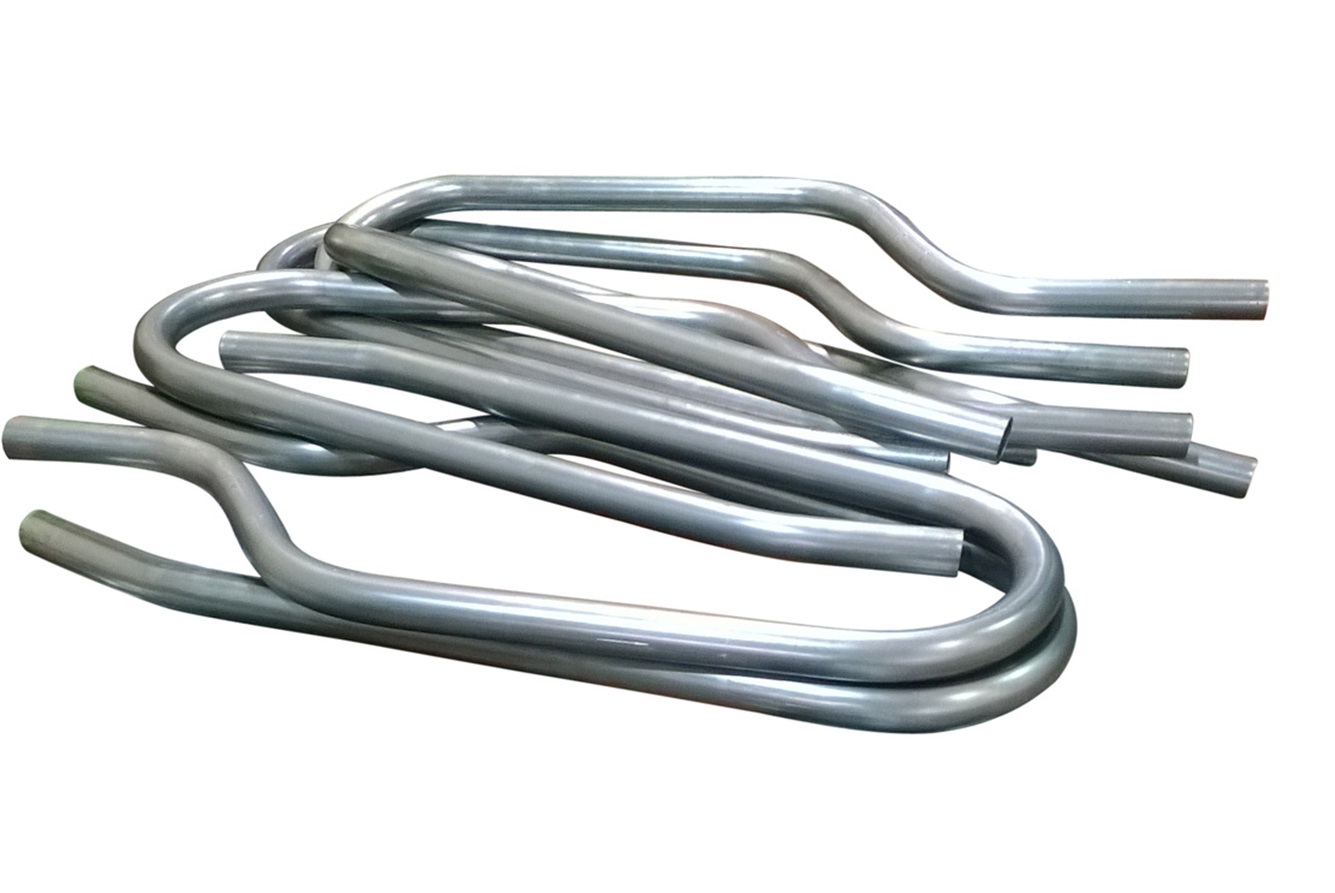

Steel tube bending involves reshaping a tube or pipe for specific applications. The challenge lies in preserving the tube’s structural integrity, as improper handling can cause the metal to crack. Therefore, only a skilled metalworker can successfully perform this intricate process.

Some of the common methods used for steel tube bedding are:

Rotary Draw Bending: This method is used when precision is paramount. This method uses a die to bend the tube around a fixed radius, ideal for tight, consistent bends. It maintains the structural integrity of the metal.

Mandrel Bending: A mandrel is inserted into the tube or pipe before it is bent to ensure that the tube does not wrinkle or snap during bending.

Roll Bending: In roll bending, a metal tube is passed through a series of rollers to bend it.

Press Bending: A press is used to apply force to the tube, bending it to the desired angle. It is suitable for simple, large-radius bends.

Multiple factors impact the bending technique, which is discussed here:

Different steel grades perform differently during bending. Generally, the harder the metal, the more challenging the bending process.

The thicker the material, the better it bends. The outer radius thins as the metal bends, while the inside radius thickens. The length of the tube also influences the bending.

The tighter the radius, the higher the risk of metal deformation. The outer radius, as it thins out, might snap.

Lubrication plays an important role in steel bending by reducing and preventing friction.

Multiple steel bender types are used to achieve perfection. These are:

As the name suggests, sheet metal benders are used to bend flat sheet metal. With the introduction of advanced machinery, creating complex bends with sheet metal benders has become easier.

Steel pipes have thicker walls compared to tubes. Steel pipe benders are used to bend these. These machines apply greater force to achieve the angle without forcing it to crack or wrinkle.

Steel tube benders are designed specifically for steel tubes, which have thinner walls than steel pipes and thus have a greater chance of snapping. They come in various types, including manual, hydraulic, and CNC (computer numerical control) benders, each suited for different applications and complexity levels.

When bending steel pipes, several factors must be considered for successful bending. Some of the factors are:

Steel pipe bending requires proper tools, which must be made of a material harder than the pipe. A workman who invests in proper tools can only achieve perfect steel bending.

The slower you bend the pipe, the more time you provide it to adjust to the change, and as a result, the metal doesn’t snap.

Preheating the metal is advised for harder steel grades to make bending easier.

A mandrel is a wire or tube inserted inside the pipe to prevent deformation. Rotary draw bending and mandrel bending are two preferred methods of steel tube bending.

If you are attempting steel tube bending, here are certain practical tips that might help you. Check these out:

Assess the metal grade and determine the right bender type. Choosing the right machine for bending can make all the difference.

Properly align the metal tube in the bender to ensure that the tube is bent at the correct angles.

Do not underestimate the power of lubrication in steel tube bending. It can save you from making costly mistakes.

Every metal has a limitation to deformation based on its thickness. You can only push it so far. So, monitor the bend radius. Otherwise, you can ruin the material, which can be impossible to mend.

Metal bending is more complex than it seems. You must possess the required tools and proper technique and must have the knowledge of the metals to achieve perfection. Thus, it is advised that you choose a professional for metal bending instead of attempting DIY steel bending. Professional steel tube benders can help you achieve the desired results without you needing to invest in costly tools and training. It also saves you precious time.

New Mexico Metals LLC is renowned for offering top-quality metal bending services in Albuquerque. We boast of having a knowledgeable staff, advanced machinery, and the expertise to offer you what you need.

Contact us for an appointment today or visit the store anytime.