Metal bending is a metal fabrication process in which the metal is not cut or sheared but bent, maintaining its strength and making it useful for multiple processes. Steel sheets, bars, or rods can be bent, thanks to metal bending tools, which achieve precise bends and ensure project success.

This guide is all about the must-have metal bending tools if you are a DIY enthusiast who undertakes metal bending. You will find everything here, including choosing the right bending tools, safety precautions, and common questions about bending steel plates or stainless steel tubing.

Steel bending refers to deforming metal into distinct angles, shapes, and curves by applying pressure. The pressure on the metal is applied through manual manipulation or mechanically, which considers the metal’s malleability and desired bend and radius to achieve the result. When bending steel plates, it is required to understand their properties, ductility, hardness, thickness, etc., to choose the right steel bending tools.

Only the right amount of pressure and tools can achieve the desired bends. Executing the right bend also requires skill and expertise.

Are you attempting steel bending? You must have these tools before you dive into it. Check these out.

Manual bending tools are simple tools with dies and handles to lever the benders and achieve precision. They are ideal for small operations to bend metal sheets and rods precisely.

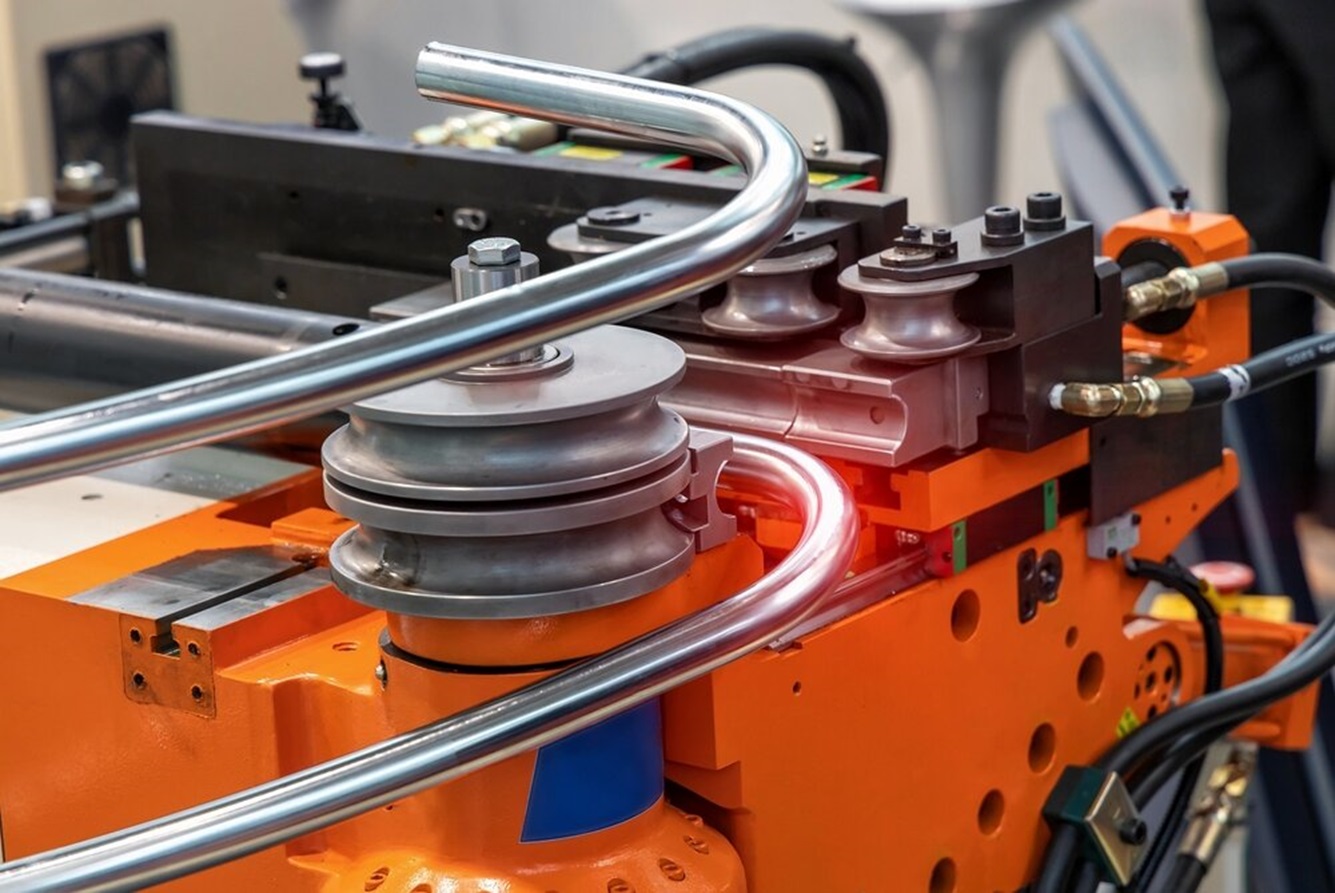

Roll benders have rotating rolls. Metal sheets, rods, or pipes are passed through the rolls, which gradually deform the metal to achieve the desired curvature.

This steel bending machine is useful for accurately bending thick metal sheets or plates. It utilizes hydraulic pressure to exert force on the metal, allowing for precise bends and complex shapes.

Bending steel sheets, rods, and tubes is quite distinct, considering the cylindrical shapes of the tubes and rods. Thus, tube and pipe benders are used to bend these cylindrical shapes. These machines come in various configurations, including manual, hydraulic, and electric, to accommodate different sizes and shapes of tubing.

If you are a DIYer and only engage in such activities occasionally, it is not wise to invest in all these metal bending machines. In such cases, you can always seek the help of an expert, New Mexico Metals LLC in Albuquerque, where you will get the best metal bending services.

Contact us today for more information!

Whatever your project is, you must choose the right tools for it. So, here is how to choose the right steel bending tools for your project:

You must assess material thickness and hardness before choosing the right tool and machine. Hard metals, such as carbon steel, are very hard and require heavy-duty equipment for operation. You are advised to visit a metal bending expert in Albuquerque for hard metals.

Can your tools achieve the desired radius and angle on the sheet metal? Some machines offer greater flexibility in adjusting bending parameters than others. So, do some research on metal bending tools and machines before you dive right into it.

How often do you engage in metal bending activities? What is your budget? Is it cost-effective to invest in a high-end machine? Ask yourself these questions and then invest in the right tool or machine. High-quality tools cost more initially, but they are reliable and long-lasting. If you are budget-conscious, then choose New Mexico Metals LLC for your metal bending needs.

Does your garage or workstation have ample space to accommodate the steel bending machine you are investing in? Evaluate the available space and then make a decision.

Steel bending means working with metals and bending machines, exposing you to the risk of injury. So, check out these safety precautions and keep yourself safe.

When working around metals, it is important to follow safety procedures. With the right tools and machines, you can successfully complete your project.

However, when dealing with hard metals and lack of the right tools and machines, choose New Mexico Metals LLC for metal bending in Albuquerque.

We are the best metal fabricators in town. We have the required experience, skills, and machines to finish your project accurately, on time, and with unmatched quality.

For metal bending services in Albuquerque, contact us anytime.

Que: Do I always need steel bending tools to bend metal?

Ans: Softer and smaller metal components can be bent using basic tools such as pliers, hammers, and grips. However, for a bigger project, you will need specialized equipment.

Que: Are there any limitations to the shapes that can be bent using roll benders?

Ans: Roll benders can help achieve multiple shapes, including flat bars, round bars, square bars, tubes, and pipes. However, the complexity of the shapes that can be bent may be limited by the diameter and curvature of the rollers and the flexibility of the material being bent.

Que: Do I need training to perform metal bending?

Ans: While complex metal bending requires skills and expertise, you don’t need training for some basic metal bends using manual metal bending machines. However, consult a metal bending expert, such as New Mexico Metals LLC, if your project is complex.