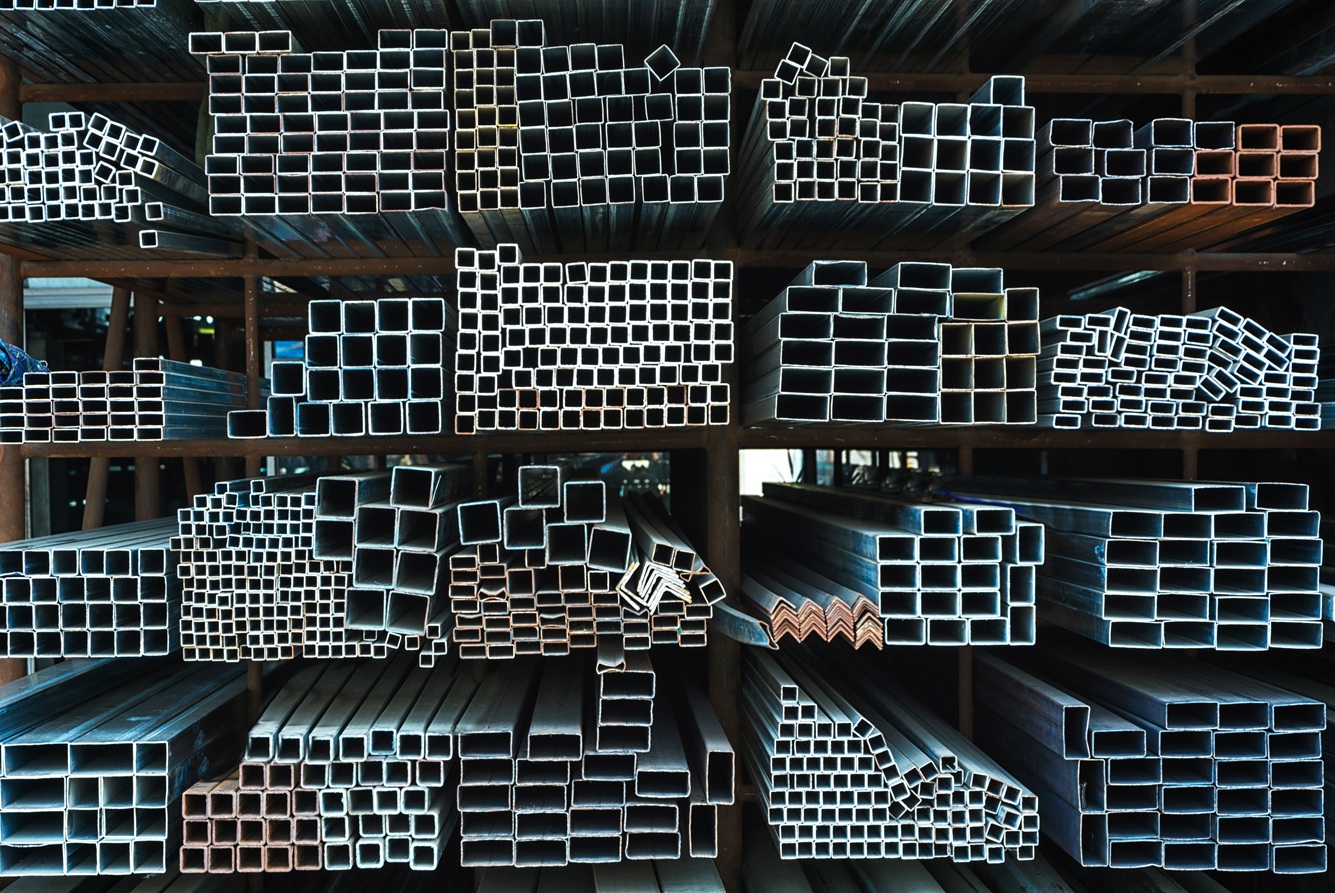

Stainless steel tubing is used for many purposes in automotive, construction, plumbing, and other industrial applications. The importance of a stainless steel tube can be understood by looking around yourself and noticing that it is used in your home as well. Its strength, corrosion resistance, and polished appearance make it a top choice for projects where both durability and aesthetics matter.

Thus, whether you are sourcing it for your home or a project, you must know how to bend stainless steel tubing and what can go wrong if it doesn’t meet the quality standards.

Following best practices, using the right steel bending tools, and hiring reliable experts are key to achieving successful results. This blog discusses them in detail, so you can avoid these mistakes or easily identify them when sourcing from a supplier.

Stainless steel is tougher and less malleable than softer metals, such as aluminum. Thus, it requires significant force and even greater precision during bending. Also, it can easily get scratches, which are visible on its polished surface. Therefore, it is crucial to handle the bending process carefully, considering key factors such as tubing thickness, diameter, and bend radius.

Selecting the right tools for stainless steel bending makes all the difference between a smooth bend and a damaged tube. Thus, use these common tools and equipment:

Manual Tube Benders: These are suitable for small and manual jobs.

Steel Bending Machines: These machines are designed to provide higher precision for large-scale bending operations.

Rotary Draw Benders: When working with tight radius, these machines are relied upon.

Mandrel Benders: They use a mandrel, which supports the tube’s interior during bending to avoid warping or cracking.

Lubricants and Finishing Products: Lubricants reduce friction, while finishing products polish the surfaces.

Never underestimate the importance of the right steel-bending tools if you want precise and consistent results.

Here is a step-by-step guide to bending stainless steel tubes with perfection:

The first step is to take accurate measurements. Use a marker that won’t scratch and prevent errors and material wastage.

What is your bend radius? Which type of metal grade are you working on? What is the meta thickness? After considering all these factors, choose the right bending tool.

Always use lubricants between the tube and the bender to prevent scratches and overheating.

Never hurry the process. Always bend slowly and apply moderate pressure. Quick, jerky movements can damage the tubing.

Inspecting the final bend is important, whether you are doing it as a professional or a hobbyist. Small imperfections can compromise the appearance and structural integrity.

Check out these best practices to preserve the bend finish:

These are expert tips to ensure that the final product maintains both functionality and appearance.

Here is a guide on when to use manual tools vs bending machines:

Manual Tools: If you have a small workshop and enjoy working with metal as a hobby, then manual tools are perfect for you. These can easily bend thin tubes and are useful for occasional small bending projects.

Steel Bending Machines: These are ideal for thicker tubing, repetitive bends, or large projects requiring consistent precision.

For industries, investing in a stainless steel bending machine is the right alternative. They offer consistency and are fit for large-scale production.

Bending a stainless steel plate works on the same bending principles, but it requires different tools and more force. It takes a press brake or a hydraulic machine, while a tube can be bent using mandrels or rotary systems.

Avoid these common mistakes during steel bending:

Learning how to bend stainless steel tubing correctly is necessary not only when working on it yourself but also when sourcing, as it can save you money. When you understand the process, you can spot mistakes and invest only in accurately and consistently bent tubes.

However, the easiest way is to hire a metal bedding expert in Albuquerque, such as New Mexico Metals LLC. Here, you will find all metal components and related services under one roof.

Contact us today!

Que: Can I bend stainless steel tubing without a bender?

Ans: You can, but it’s not recommended as it can lead to flattening, kinks, or surface damage. Always use proper benders.

Que: What’s the best tool to use for bending stainless steel tubing?

Ans: Rotary draw benders or mandrel benders are best suited for tubing, as they maintain the shape and finish of the tubing.

Que: How can I prevent cracking or flattening during a bend?

Ans: Use the right bend radius, apply lubrication, and bend slowly with consistent pressure.

Que: Is bending a steel plate the same as bending tubing?

Ans: No. While the bending principles are the same, the bending tools for the two are very different.

Que: Will bending stainless steel tubing weaken it?

Ans: Slight weakening may occur due to stretching, but when done properly with the correct radius and tools, the tubing remains structurally sound and fit for use.