Multiple projects at home also require metal drilling. Drilling one simple hole in a metal sheet requires skill, and you cannot always rely on experts.

However, if you are attempting it yourself, you should always learn from the best to do it right when you undertake the drilling project.

For all DIY enthusiasts, if you are looking for a guide on the best metal drilling techniques, you are on the right page.

We are New Mexico Metals LLC, the best steel supplier in Albuquerque and metal drilling experts. If you get stuck, you can always approach us for your project, and we’ll be happy to help you out!

Let’s dive into the best metal drilling DIY guide now.

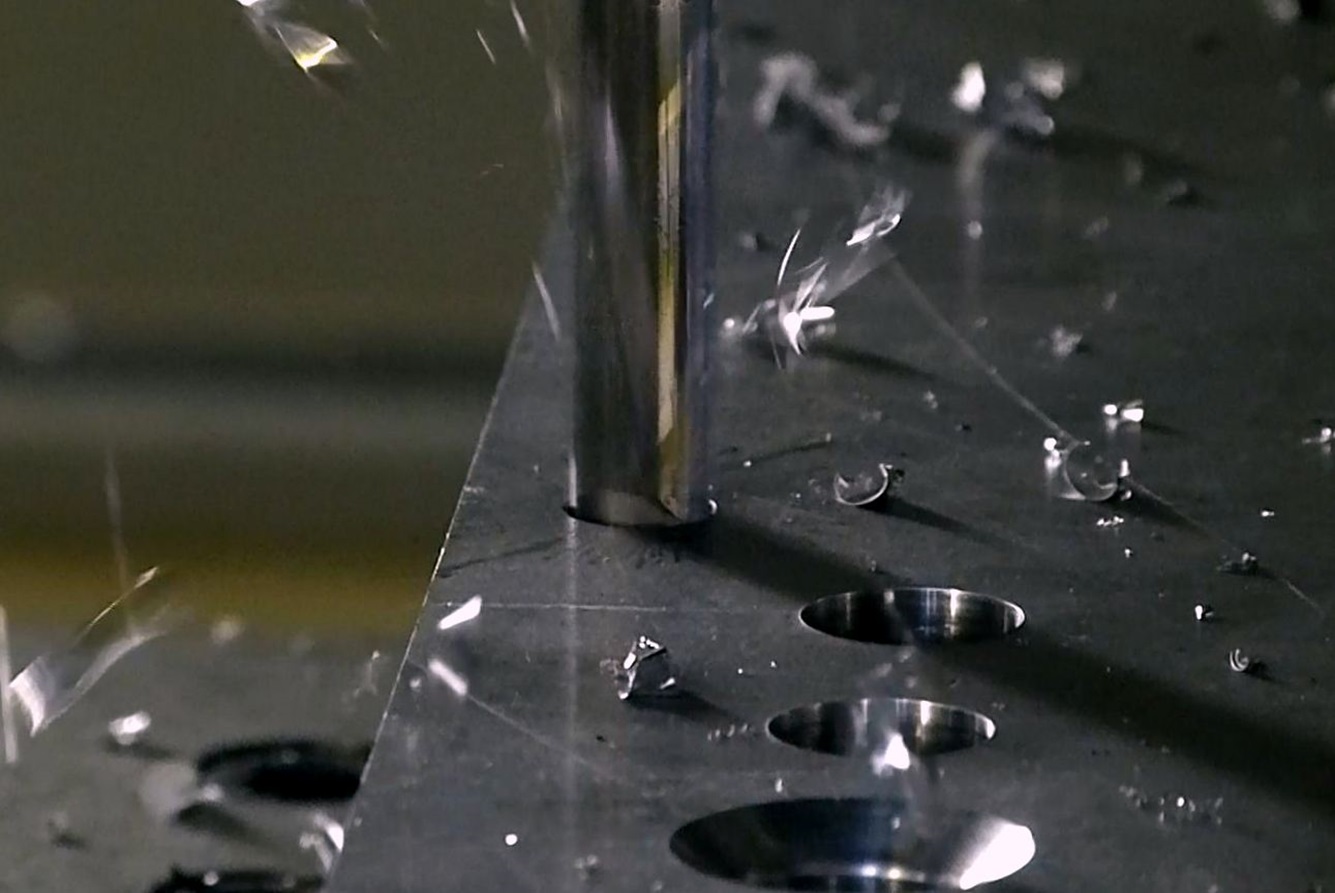

Metal drilling refers to creating holes in metal for multiple purposes, including product assembly, ventilation, etc. Metal drilling is not as straightforward as drilling wood or plastic, as metal is very hard and requires the right skill set to achieve excellence. In addition, understanding the tools at your disposal and the metal you are drilling is crucial for effective drilling.

You need the right tools to achieve the greatest results and excellence in your work. Here is a list of all the metal drilling essentials.

Of course, you need a drilling machine if you are drilling. There are two types of power drills that you can use: hand drills and power drills. Hand drills are manual, and you must rotate them bit by bit to carve a hole. On the other hand, power drills are the most common type of drill, and they are widely used in metal fabrication. They are powered by electricity and are quite easy to carve holes with.

A drill cannot work without its drill bits. Drill bits are small, pointed tools that are an indispensable part of the drilling machine. When rotated, they scoop off the metal from the sheet. There are different types of drill bits, such as cobalt, stainless steel, HSS, etc.

As the metal is drilled, it generates heat, which can damage the drill bits and the metal itself. Thus, lubricants are used to reduce friction and improve drill quality.

For every metal project, you need a stable, clean, and clutter-free workstation. This will contribute to the stability of the metal piece under operation and allow effective metal drilling. Ensure that your metal workstation is at the right height and can bear the brunt of machines. If you are not investing in multiple tools, you can use a table as your workstation.

Clamps or vises are essential for every metal fabrication technique. They secure the metal workpiece in place and prevent movement during drilling.

A center punch is a tool for creating an indentation in the metal before using the drilling machine.

A deburring tool is used to remove any sharp edges or burrs from the drilled hole for a clean finish.

These essential tools must be in your garage before you commence any drilling project. If you need help, call us at New Mexico Metals LLC for expert metal drilling services in Albuquerque.

Many DIY enthusiasts claim to have all the right tools but still end up with a messed-up drilling job. The reason might be choosing the wrong drill bit, which makes all the difference in metal drilling operations.

Here are some factors you should consider when choosing a metal drill bit.

Is your drill bit compatible with the metal that you are drilling? Understanding metal properties is crucial here. Cobalt or carbide drill bits must be preferred when drilling stainless steel or titanium. You can also use HSS drill bits for multiple metals.

You must choose the drill bit based on the desired size and diameter of the hole. Using an oversized or undersized drill will pose challenges.

Drill bits come in different point angles, such as 118 degrees or 135 degrees. Choose one based on metal type and thickness.

These drill bit types are used for specific operations such as enlarging existing holes or creating countersinks.

Drilling metal is a task that should generally be undertaken by those with more experience. It requires specialized tools, a certain skill set, and expert knowledge, making it advisable to seek professional assistance for such projects. So, if your DIY metal drilling project did not succeed, or you require any help, visit us at New Mexico LLC, the best steel supplier in Albuquerque.

Que: How can drill bit breakage be prevented during drilling?

Ans: The answer lies in choosing the right drill bit for the project. Always use a sharpened and well-aligned drill for effective metal drilling. Also, use lubricant to avoid excessive heating.

Que: Can I use regular drilling bits?

Ans: Regular drill bits are good, but they cannot be used to drill different metals. You can utilize them for aluminum or copper but not for other harder metals.

Que: Is there a certain speed for drilling metals?

Ans: Yes, the speed of metal drilling depends on the material thickness, the type of hole you need, the size and type of drill bit, etc.