Stainless steel sheets are versatile, and thanks to their wonderful corrosion resistance properties, they are in demand for multiple reasons. As the consumer, you look for a durable metal that lasts decades. However, a lack of knowledge about stainless steel sheets can cause you to end up with the wrong material for your needs.

In this blog, you will find comprehensive details about stainless steel sheets, their properties, applications, factors to consider when choosing the right type, and other details. Read on.

Today, everywhere you see, you will find stainless steel, be it construction, medical field, automotive, or kitchen appliances. Stainless steel sheets are available in various grades and finishes, each tailored to specific applications and environments.

The different grades of stainless-steel sheets include grades 316, 302, 305, 304, 430, 414, 440, etc. Apart from this, the grades are divided based on the alloys that are used to manufacture them. You will learn about them further in the blog.

Stainless steel sheets are used in various manners based on the needs of the specific industry. For example, industrial metals require stamping before they are put to further use, sent for assembly, or cut down into pieces for multiple industries.

The various industries where stainless sheets are used are:

Medical equipment requires the highest quality of stainless-steel grades. They are used for manufacturing of surgical equipment, medical fixtures, machinery, etc.

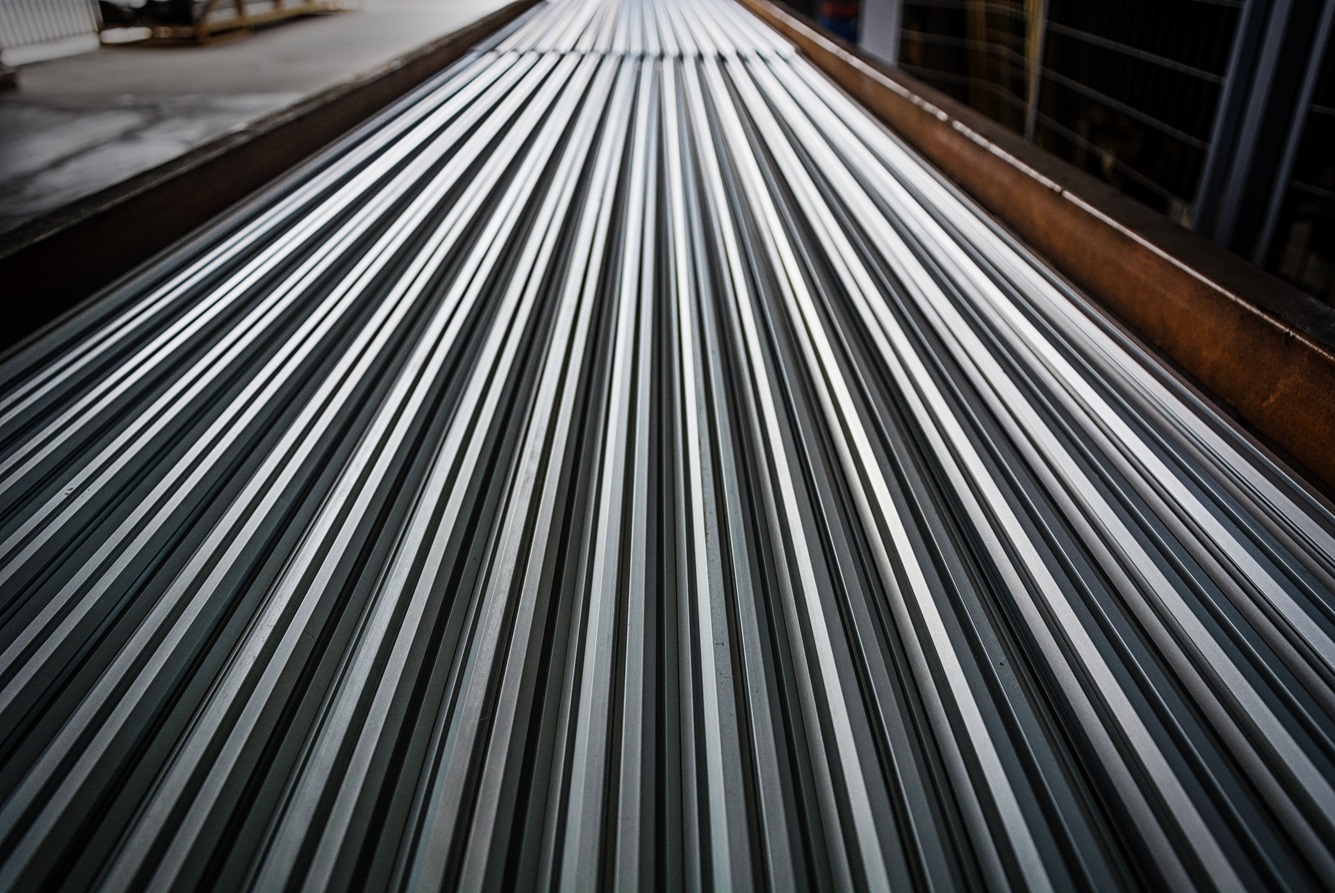

Stainless steel sheets have offered unmatchable strength, durability, and corrosion resistance to structures worldwide; thus, the sheets are used extensively in the construction industry. They are used to manufacture scaffolding, roofing, wall cladding, etc.

Multiple parts of vehicles, such as car exhaust systems, seatbelt springs, hose clamps, etc., are made of stainless steel.

Your kitchen must be safe, and it should have no space for rusting. Thus, stainless steel is used extensively for manufacturing kitchen equipment, including knives, utensils, kitchen countertops in commercial spaces, etc. Multiple kitchen appliances, including microwaves, refrigerators, dishwashers, etc., are also made of stainless steel.

The marine and aerospace industry requires robust steel that is unaffected by atmospheric pressure, excessive exposure to heat, moisture, and other environmental effects. Thus, stainless steel stands out as the most suitable metal.

Industrial metals are exposed to harsh environments and demand stainless steel machinery and other accessories to survive the conditions.

Artists are taking an active interest in creating intricate artistic sculptures and designs with stainless steel, which renders their creations durable and aesthetically pleasing.

When selecting stainless steel sheets for a specific application, several factors should be considered:

Grade: As discussed, stainless steel sheets are available in multiple grades, and the right one shall be chosen for the underlying task, considering the grade characteristics.

Thickness: Based on the grade’s structural requirements and mechanical properties, choose the right stainless steel sheet thickness that will make your project successful.

Surface Finish: Industrial metals don’t focus primarily on aesthetics, but that’s not the case with artistic endeavors. The crux is that different purposes require different stainless steel sheet grades, which come in multiple surface finishes. Hot-rolled finished steel sheets are used where aesthetics is not important; on the other hand, cold-rolled finished steel has a beautiful matte appearance, smooth and beautiful. Based on the project requirements, choose the right surface finish.

Cost: Cost is the deciding factor in most cases. So, determine a budget and then peruse stainless steel sheet grades considering the above factors.

When you are an amateur, choosing the right stainless steel sheet grade can be overwhelming, considering your lack of knowledge. You need a reliable steel supplier in Albuquerque who can fulfill your needs and offer the best quality stainless steel sheets. Looking for a supplier with a diverse inventory, competitive pricing, and a track record of delivering high-quality products and excellent customer service is crucial.

Thus, look no further than New Mexico Metals LLC, Albuquerque, where we offer the best quality metals, procured from the best manufacturers in the country and brought to you affordably.

We also pride ourselves on being the best metal stamping service provider where you can get on-time service at the best rates.

Metal stamping is the process of forming, punching, and notching metal sheets to render them useful for further processes. Metal stamping is a crucial operation that ensures that metal sheets are precisely stamped, or else the metal might become useless.

At New Mexico Metals LLC, we boast of having trained professionals who perform every operation, no matter how small it is, with precision and utmost care, so you trust only New Mexico Metals LLC for your metal-related needs.

In conclusion, stainless steel sheets offer a versatile solution for various applications across various industries. This blog is an attempt to help you learn about the considerations before choosing the right grade, the multiple applications, and how to make an informed decision.

However, if you need any help, contact us at New Mexico Metals LLC, and we will be happy to help.