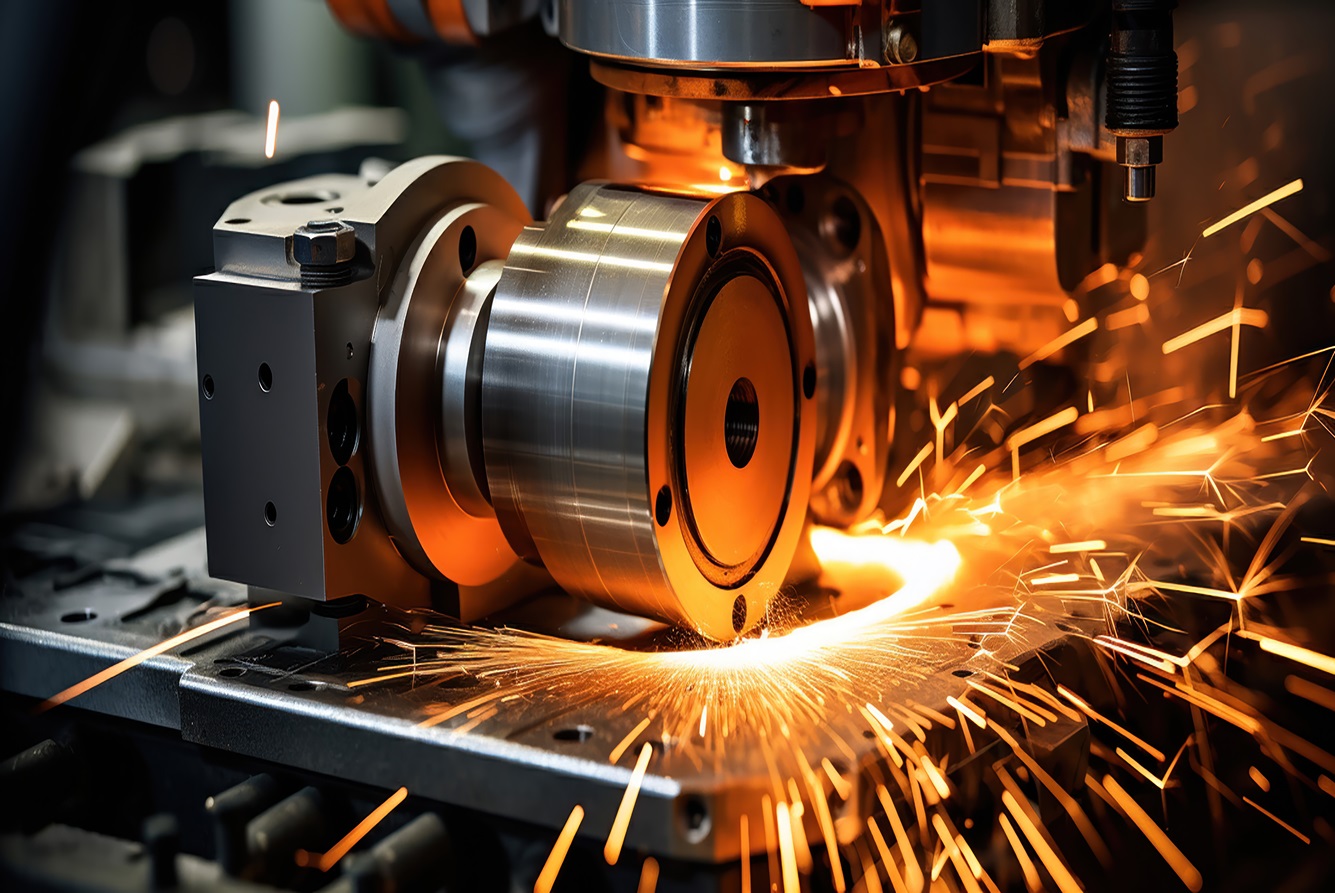

Metalworking is an art that takes form with the help of the right tools. It takes more than just metals and machines to transform metal; it is a combination of precision, skills, and the right set of tools to convert a simple raw metal into something useful and aesthetically beautiful. Transforming metal requires bending, cutting, punching, notching, and other techniques.

Metal punching and notching are two techniques that carve different patterns in metal, while metal bending deforms a metal sheet without cutting it.

To achieve this, you require different metalworking tools, which have been discussed in this blog. Read on!

Metal punching is the process of punching holes in a metal sheet for multiple purposes. A punch and die set are used to forcefully remove a metal piece from the sheet. Metal punching can be achieved through manual or automatic processes.

Not only holes but modern metal punching machines can carve beautiful designs and patterns in the metal with commendable ease.

Check out these metal punching tools used for both manual and machining processes.

Manual tools can be used for smaller projects where time and volume aren’t the deciding factors. Manual punching is possible when you are working on thin sheets. It is a labor-intensive task that requires skill and precision. The tools used are hammers, hand punches, manual lever-operated punch presses, etc. These tools are useful when you have a small workshop or engage in metal works as a hobby.

As the name suggests, hydraulic machines use hydraulic power to punch metal. These machines are huge and powerful, mainly used in industrial operations that require multiple metal grades to be punched in bulk. They can easily punch through thicker metals and offer higher efficiency and precision.

Computer Numerical Control (CNC) punching machines are the most advanced option, offering high precision and automation. These machines follow a defined pattern and can carve even the most complex designs on a metal sheet. When consistency and accuracy are desired, CNC punching is the answer.

Choosing a metal punching machine for metal works? There are certain factors that you must consider. Check these out:

Material: Every metal is different, with distinct strength and ductility. Using the wrong machine can result in both metal wastage and tool breakage. Thus, assess the material carefully before choosing the machine.

Thickness: The thickness of the material determines the type of metal punching machine needed. For instance, you cannot punch thick metal using a manual punch and die; a hydraulic machine is required for that.

Hole Size or Pattern: When it comes to simple holes or squares, manual punch can achieve the goal, but if you need complex patterns, then CNC punching is advised.

Production Volume: For large production volumes where consistency and accuracy are crucial, CNC punching machines are the best choice.

Metal punching requires you to possess enough knowledge of the metals and machines and the skills to produce results.

The first prerequisite of metal punching is that the metal should be precisely aligned. Using marking tools and aligners is advised.

One should always check the metal punching tools before the punching operation. Check whether the punches and dies are sharp enough to pierce the metal. If not, they can cause burrs and distort the metal. Lubrication is the key to achieving smoother cuts and holes.

Metal punching, along with other processes like cutting, bending, and welding, works together to streamline production and improve efficiency. For example, creating a metal bucket involves cutting the metal, bending it into a cylindrical shape or cone, welding the seams, punching holes for the handles, and finishing the product.

Metal bending can be performed before or after the metal punching, giving the sheet metal a specific shape and structure.

Metal cutting before the punching ensures that metal sheets are cut the right size and are easy to tackle under the machine, especially during manual operations.

Different metal services require different tools and specific skills for desired results. Metal goes through multiple processes to make it useful for various industries. This blog has covered some of the metal works and techniques and which tools are used. For detailed information on other topics, you can explore our blogs.

For quality services, you can confidently rely on New Mexico Metals LLC. With years of experience, advanced tools, professional and friendly staff, and in-depth knowledge of metal and metal works, we boast of providing the best metal products and services in Albuquerque.

Contact us today for more information!